Solar Panel Installation in the UK: Complete 2026 Guide for Homeowners

Solar panel installation in the UK involves a structured process managed by MCS-certified professionals, typically completing within 4-8 weeks from initial survey through final grid connection. Residential installations cost £5,000-£12,000 for complete systems in 2026, with the physical installation taking 1-3 days depending on system complexity. Understanding the installation stages, certification requirements, and regulatory approvals ensures homeowners make informed decisions and avoid costly delays or compliance issues.

Table of Contents

ToggleWhat is the solar panel installation process in the UK?

The UK solar panel installation process follows standardised steps governed by MCS certification requirements and Building Regulations compliance. Initial property assessment determines roof suitability, followed by system design, DNO grid connection approval, physical installation, testing and commissioning, and final MCS certificate issuance. MCS-certified installers handle regulatory paperwork including G98 or G99 applications to Distribution Network Operators, ensuring systems meet safety standards and qualify for Smart Export Guarantee payments ranging from 4p-17.5p per kWh in 2026.

Initial Property Assessment and Survey

MCS-certified installers conduct remote or in-person property assessments evaluating roof condition, orientation, shading, structural capacity, and electrical infrastructure. UK roofs typically support solar panel system weights of 10kg per square metre without reinforcement, though hipped roofs, vaulted ceilings, and flat roofs may require structural surveys confirming load-bearing capacity. Surveyors assess roof pitch (ideally 30-45 degrees for optimal generation), orientation (south-facing preferred, though east-west arrays suit certain usage patterns), and shading from trees, chimneys, or neighbouring buildings affecting system performance.

Remote surveys require homeowners to provide photographs of roof areas, electricity meters, consumer units, and proposed battery and inverter locations. Video surveys enable installers to assess loft spaces, rafter conditions, and cable routing options without site visits. In-person surveys become necessary for complex installations involving listed buildings, conservation areas, or properties requiring structural modifications before panel installation.

Assessments identify optimal panel placement maximising annual generation while considering aesthetic preferences and future roof maintenance access. Installers evaluate consumer unit capacity, confirming adequate spare ways for solar connections and identifying any necessary electrical upgrades before installation proceeds. Properties with older consumer units lacking RCD protection or insufficient capacity require upgrades costing £300-£800 before solar installation commences.

System Design and Equipment Selection

Installers design bespoke solar systems matching household electricity consumption patterns, available roof space, and budget constraints. Design considerations include panel quantity (typically 8-16 panels for residential properties), total system capacity (3kWp-10kWp ranges), inverter type (string inverters, microinverters, or hybrid inverters), and optional battery storage integration (5kWh-15kWh capacities). System designs specify panel layout across multiple roof planes if necessary, accounting for shading mitigation through microinverters or power optimisers.

Modern installations in 2026 predominantly use monocrystalline panels rated 400W-550W with efficiencies of 20-23%, requiring fewer panels than older technologies for equivalent capacity. Panel selection balances efficiency, aesthetics (all-black versus black-and-silver frames), warranty terms (25-40 years product warranties), and cost (£150-£450 per panel depending on manufacturer and specifications). Premium manufacturers including SunPower, LONGi, and AIKO offer superior efficiency and extended warranties at higher costs, while mainstream brands provide reliable performance at competitive prices.

Understanding options when buying solar panels helps homeowners make informed equipment choices, comparing manufacturer warranties, efficiency ratings, and pricing structures before accepting installer proposals.

Inverter selection depends on system architecture, with string inverters costing £800-£2,000 serving entire arrays, microinverters at £100-£200 per panel optimising individual panel performance, and hybrid inverters integrating battery storage functionality. Microinverters suit installations with complex roof layouts or partial shading, enabling panel-level monitoring and preventing single panel issues from affecting entire system output. Hybrid inverters future-proof installations for battery addition, though AC-coupled batteries provide retrofit flexibility for existing string inverter systems.

Planning Permission and Building Regulations

Most UK domestic solar installations qualify as permitted development, exempting them from planning permission requirements under permitted development rights. Installations must not protrude more than 200mm from roof plane, panels must not extend beyond roof edges, and installations on buildings within conservation areas face restrictions on visibility from highways. Listed buildings, properties in designated conservation areas, World Heritage Sites, or Areas of Outstanding Natural Beauty require planning permission regardless of installation size or location.

Flat roof installations added to permitted development rights in December 2023, provided panels do not exceed 1 metre height above roof surface and installations meet size restrictions (no more than 50% of original property footprint). Ground-mounted installations require planning permission if exceeding 9 square metres, positioned within 5 metres of property boundaries, or standing more than 4 metres high at any point.

MCS-certified installers ensure Building Regulations compliance through proper electrical installation adhering to BS 7671 18th Edition wiring regulations, structural integrity verification, and fire safety measures. Installations receive Building Regulations compliance certification confirming electrical safety, structural adequacy, and proper earthing and surge protection implementation. This documentation proves essential for property sales, insurance claims, and warranty enforcement throughout system lifespan.

DNO Application and Grid Connection Approval

Solar systems exceeding 3.68kWp capacity require Distribution Network Operator approval before grid connection, ensuring local electrical networks can accommodate additional generation without destabilising supply. The UK divides into 14 regional DNO areas operated by six companies including UK Power Networks, Northern Powergrid, Scottish and Southern Electricity Networks, and Western Power Distribution. Homeowners identify their DNO through electricity bills or the Energy Networks Association postcode checker, though MCS installers typically handle entire application processes.

G98 applications cover systems up to 3.68kWp per phase (11.04kWp for three-phase supplies), typically processing within 5-10 working days through automated approval systems. These simplified applications require basic system specifications without detailed technical submissions, making them suitable for smaller residential installations. G99 applications govern systems exceeding G98 thresholds, requiring detailed technical information including inverter specifications, protection settings, and connection diagrams, with approval timeframes extending to 2-8 weeks depending on DNO workload and local network capacity.

DNO applications specify installation capacity, inverter models, connection types, and export limitation settings if required. Some areas with high solar penetration impose export limitations restricting maximum grid export to percentages of system capacity, though most domestic installations receive unrestricted export approval. Failed DNO applications due to network capacity constraints occur rarely, typically affecting large commercial installations or areas with concentrated solar deployment exceeding local infrastructure capabilities.

MCS-certified installers submit DNO applications on behalf of homeowners, tracking approval status and coordinating installation scheduling around confirmation receipt. Proceeding with installation before DNO approval risks non-compliance penalties, system disconnection requirements, and Smart Export Guarantee ineligibility. Completed installations receive DNO commissioning confirmation enabling export tariff applications and legal grid connection operation.

| Criteria | G98 Application | G99 Application |

|---|---|---|

| SYSTEM CAPACITY | ||

| Single-Phase Systems | Up to 3.68kWp (3.68kW) | Above 3.68kWp (3.68kW) |

| Three-Phase Systems | Up to 11.04kWp (11.04kW) | Above 11.04kWp (11.04kW) |

| Typical Residential Range | 8-10 panels (3.2-4kWp) | 12-25 panels (4.8-10kWp) |

| APPLICATION PROCESS | ||

| Submission Method | Automated online portal | Detailed technical submission |

| Technical Documentation | Basic system specs | Full technical specifications |

| Inverter Details Required | Model number, capacity | Model, protection settings, G99 compliance |

| Connection Diagram | Not required | Required |

| Protection Settings | Standard defaults | Detailed loss of mains, voltage/frequency |

| PROCESSING | ||

| Typical Approval Time | 5-10 working days | 2-8 weeks |

| DNO Response | Automated approval | Technical review, potential queries |

| Site Visit Required | Rarely | Sometimes (network capacity concerns) |

| Network Impact Assessment | Automated | Manual engineering review |

| COSTS & FEES | ||

| DNO Application Fee | £50-£100 | £100-£250 |

| Connection Fee | Usually £0 | £0-£500 (if network upgrades needed) |

| Post-Installation Reporting | Online form completion | Commissioning report submission |

| RESTRICTIONS | ||

| Export Limitations | Rare in residential areas | May apply in high-solar areas |

| Installation Timing | Proceed after approval | Must wait for approval |

| System Modifications | Notify DNO if capacity changes | Reapplication if >10% change |

| Grid Connection Point | Existing meter point | May require dedicated connection |

| INSTALLER REQUIREMENTS | ||

| Who Can Submit | MCS-certified installers | MCS-certified installers |

| Electrical Qualifications | 18th Edition wiring regs | 18th Edition + G99 knowledge |

| Professional Indemnity Insurance | £2m minimum | £5m minimum (some DNOs) |

| AFTER APPROVAL | ||

| Commissioning Requirements | Standard electrical tests | Detailed commissioning report |

| DNO Notification | Online confirmation post-install | Submit test results, witness test possible |

| Annual Reporting | None | Some DNOs require generation data |

| Modification Procedures | Simple notification | Full reapplication if significant |

How long does solar panel installation take in the UK?

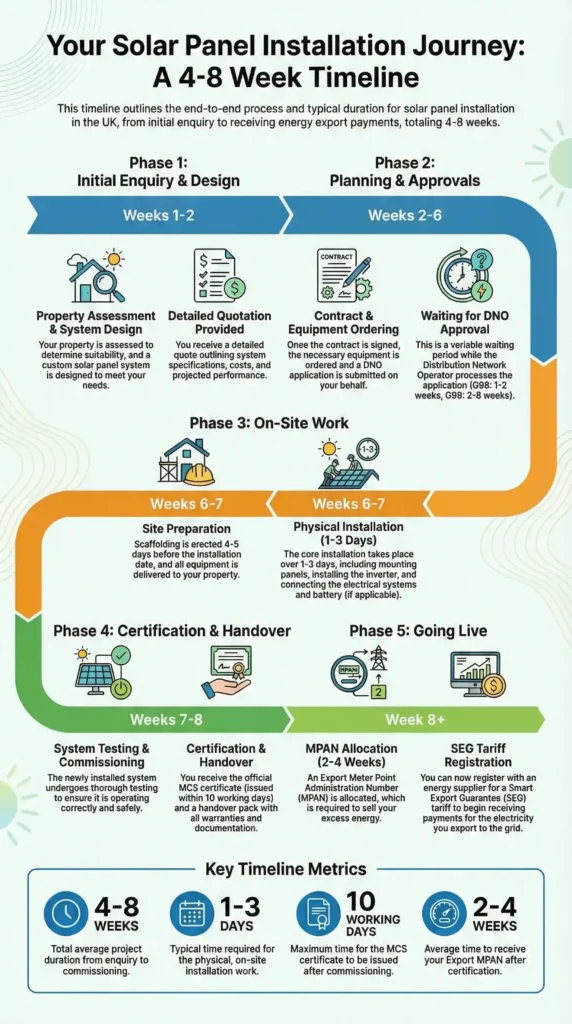

Solar panel installation duration varies from 4-8 weeks total project timeline, with physical on-site installation typically completing within 1-3 days depending on system complexity, roof access, and weather conditions. Pre-installation stages including surveys, design finalisation, equipment procurement, and regulatory approvals account for 3-7 weeks, while scaffolding erection occurs 4-5 days before installation commencing. Larger systems exceeding 6kWp, complex roof geometries, battery storage integration, or consumer unit upgrades extend installation timelines by 1-2 additional days.

Pre-Installation Timeline

Initial enquiry through quote acceptance typically spans 1-2 weeks, encompassing property assessment, system design presentation, quotation review, and contract finalisation. Reputable installers provide detailed quotations specifying panel quantities, equipment brands and models, inverter types, battery options if selected, warranty terms, installation inclusions, and payment schedules. Homeowners should compare minimum three MCS-certified installer quotations, evaluating total costs, equipment specifications, warranty coverage, customer reviews, and installer certifications before selecting preferred contractors.

Equipment procurement following contract signing requires 1-2 weeks for stock confirmation and delivery scheduling. Popular panel brands including LONGi, JA Solar, Trina Solar, and UKSOL maintain UK distributor networks ensuring relatively short lead times, though premium manufacturers or custom specifications may extend procurement periods. Inverter availability from manufacturers including SolarEdge, GivEnergy, Solis, and Growatt determines scheduling flexibility, with stock shortages occasionally delaying projects by additional weeks.

DNO application processing occupies 1-6 weeks depending on application type and regional DNO workload. G98 applications for systems under 3.68kWp process within 5-10 working days, while G99 applications for larger systems require 2-8 weeks for technical review and approval. Installers submit DNO applications early in project timelines, progressing other preparation tasks during approval periods to minimise overall delays. Some DNOs offer fast-track processing for MCS-certified installers with established approval track records, reducing typical waiting periods.

| Project Stage | Duration | Key Activities | Deliverables | Dependencies |

|---|---|---|---|---|

| Initial Enquiry & Assessment | 3-7 days | Remote/in-person survey, roof inspection, electrical assessment, shading analysis | Property assessment report, preliminary quote | None |

| System Design & Quotation | 3-5 days | Panel layout design, equipment selection, generation estimates, quotation preparation | Detailed quote, system design diagrams, performance predictions | Survey completion |

| Contract & Planning | 2-4 days | Contract signing, planning permission check (if required), deposit payment | Signed contract, payment confirmation | Quote acceptance |

| DNO Application Submission | 1-3 days | G98 or G99 application preparation, technical documentation, submission to DNO | DNO application reference number | Contract signed |

| Equipment Procurement | 7-14 days | Panel ordering, inverter ordering, mounting equipment, electrical components | Equipment delivery confirmation | Contract signed, payment received |

| DNO Approval Waiting | 5-10 days (G98) or 14-56 days (G99) | Application processing, network capacity assessment, approval issuance | DNO approval certificate | Application submitted |

| Pre-Installation Preparation | 4-5 days | Scaffolding erection, equipment delivery to site, final access arrangements | Site ready for installation | DNO approval, equipment received |

| Physical Installation | 1-3 days | Mounting installation, panel positioning, electrical connections, inverter setup, battery installation | Installed system | Scaffolding erected, equipment on-site |

| Testing & Commissioning | 4-8 hours | Electrical testing, inverter configuration, battery commissioning, system activation | Test certificates, commissioned system | Installation complete |

| MCS Certification | 1-10 working days | Installation registration, certificate issuance, database entry | MCS certificate | Final payment received, system commissioned |

| Export MPAN Allocation | 7-28 days | DNO processing, meter registration, MPAN issuance | Export MPAN number | MCS certificate issued |

| SEG Tariff Registration | 3-7 days | Application submission, documentation review, account setup | SEG tariff active, first export reading | Export MPAN allocated |

Installation Day Schedule

Installation teams arrive early morning (typically 8:00-9:00am) to commence work, beginning with scaffolding inspection and equipment unloading. Homeowners must ensure clear access to installation areas including roofs, lofts, consumer units, and designated battery/inverter locations. Teams require access throughout installation days but homeowners need not remain home constantly, provided initial access granted and installers can secure properties when departing.

Day 1 typically involves mounting system installation, panel positioning, and initial electrical connections. Installers lift roof tiles (or secure mounting points on flat roofs), fix mounting brackets to rafters using stainless steel fixings, attach horizontal or vertical rail systems to brackets, and secure panels to rails using clamps. Proper waterproofing around penetration points prevents future leaks, with installers using rubber grommets, weatherproof sealants, and careful tile replacement ensuring rain ingress prevention. Slate roofs require additional care due to tile brittleness, sometimes necessitating tile replacement or custom bracket fabrication.

Electrical connections progress from DC panel wiring through loft spaces or external conduit to inverter locations, typically in garages, lofts (with adequate ventilation), utility rooms, or protected external positions. Installers run AC cables from inverters to dedicated solar consumer units or existing consumer unit spare ways, incorporating appropriate circuit protection, isolation switches, and earth bonding. Battery installations, if included, involve mounting battery units (wall-mounted or floor-standing), connecting to hybrid inverters or AC coupling systems, and configuring charge/discharge parameters matching household usage patterns.

Day 2 and potential Day 3 complete electrical connections, conduct comprehensive system testing, commission equipment, and restore property to pre-installation condition. Testing includes insulation resistance measurements, earth continuity verification, inverter configuration and WiFi connectivity setup, battery commissioning and parameter programming, and complete system functionality verification. Installers provide handover demonstrations explaining system monitoring, emergency shutdown procedures, and basic maintenance requirements.

Post-Installation Completion

Scaffolding remains in place 5-14 days following installation completion, enabling quick rectification if any issues emerge during initial operation. Conscientious installers leave scaffolding longer (1-2 weeks) despite higher hire costs, demonstrating confidence in installation quality and commitment to customer satisfaction. Scaffolding removal requires half-day site visits, with costs typically included in quoted installation prices.

MCS certification issuance occurs within 10 working days following installation completion and final payment receipt. MCS certificates prove system compliance with certification scheme standards, enabling Smart Export Guarantee tariff applications and satisfying warranty registration requirements. Installers register installations with the MCS Installation Database, generating unique certificate numbers linking systems to installer credentials and equipment specifications. Homeowners receive certificate copies alongside equipment warranties, installation warranties, Building Regulations compliance certificates, and DNO approval confirmations.

Export MPAN (Meter Point Administration Number) allocation follows MCS certification, with DNOs typically issuing export MPANs within 1-4 weeks of application submission. Export tariff providers require export MPANs before registering systems for payment, creating potential delays between installation completion and payment commencement. Some progressive suppliers including Octopus Energy process applications using pending MPAN statuses, backdating payments to installation dates once MPANs confirm.

How much does solar panel installation cost in the UK in 2026?

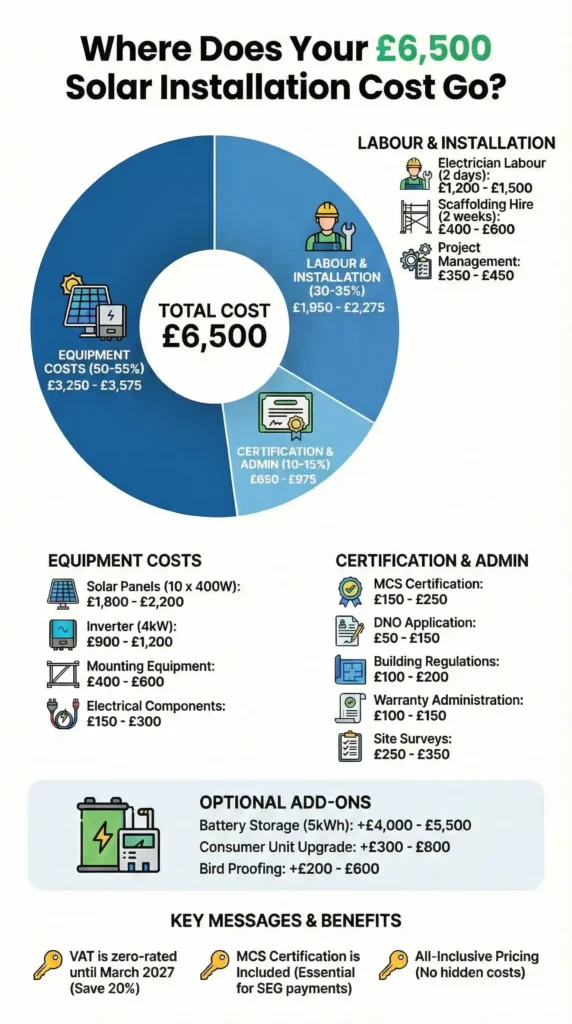

Solar panel installation costs in the UK range from £5,000-£12,000 for complete residential systems in 2026, with typical 4kWp installations averaging £5,500-£7,000 including panels, inverters, mounting equipment, labour, scaffolding, and MCS certification. System costs vary based on capacity (3kWp-10kWp residential range), equipment quality (mainstream versus premium manufacturers), installation complexity (roof access difficulty, electrical upgrades required), and optional battery storage addition (adding £4,000-£8,000 depending on capacity). VAT zero-rating applies to qualifying residential installations until March 2027, saving 20% compared to previous standard VAT-inclusive pricing.

For detailed breakdowns of equipment pricing, regional variations, and long-term solar panel costs including payback calculations, homeowners should review comprehensive cost analysis before committing to installations.

Equipment Cost Breakdown

Solar panels account for 30-40% of total installation costs, with 400W-550W monocrystalline panels priced £150-£450 per unit depending on manufacturer tier. Mainstream Tier 1 manufacturers including LONGi (£170-£250 per panel), JA Solar (£160-£240), and Trina Solar (£165-£245) provide reliable performance with 25-30 year warranties at competitive pricing. Premium manufacturers including SunPower Maxeon (£350-£450 per panel with 40-year warranties), AIKO ABC modules (£300-£400 with advanced efficiency), and UKSOL panels (£220-£320 with British family ownership) command price premiums justified by superior efficiency, extended warranties, and enhanced aesthetics.

Inverters represent 10-15% of installation costs, with string inverters ranging £800-£2,000 for 3kW-10kW residential capacities. Hybrid inverters integrating battery storage functionality cost £1,200-£3,000 depending on power ratings and battery compatibility specifications. Microinverter systems using Enphase or APsystems technology cost £100-£200 per panel (£800-£3,200 for 8-16 panel systems), providing panel-level optimisation and monitoring at higher equipment costs offset by improved performance in partially shaded installations.

Mounting equipment including brackets, rails, and fixing hardware contributes £300-£800 to total costs depending on roof type and installation complexity. Pitched roof installations use standard roof hook and rail systems, while flat roof installations require ballasted mounting frames or penetration-secured tilt frames adding £200-£400 to mounting costs. Ground-mounted systems necessitate foundation construction (concrete footings or pile-driven posts) and structural frameworks, significantly increasing equipment and labour costs to £8,000-£15,000 for equivalent capacities.

| Cost Component | Quantity/Specification | Unit Cost | Subtotal | Percentage of Total | Notes |

|---|---|---|---|---|---|

| EQUIPMENT COSTS | £3,400 | 52% | |||

| Solar Panels | 10 x 400W monocrystalline | £200 per panel | £2,000 | 31% | LONGi, JA Solar, or equivalent Tier 1 |

| String Inverter | 1 x 4kW hybrid-ready | £1,100 | £1,100 | 17% | SolarEdge, GivEnergy, or Solis |

| Mounting Equipment | Rails, brackets, fixings | £250 total | £250 | 4% | Stainless steel, waterproof gaskets |

| Electrical Components | Cables, isolators, protection | £50 total | £50 | <1% | DC cables, AC cables, MCBs, SPDs |

| LABOUR & SERVICES | £2,200 | 34% | |||

| Installation Labour | 2 installers x 2 days | £550 per day | £1,100 | 17% | MCS-certified electricians |

| Scaffolding Hire | 2 weeks | £450 total | £450 | 7% | Two-storey property access |

| Project Management | Coordination, scheduling | £350 total | £350 | 5% | Survey to handover management |

| System Testing | Electrical testing, commissioning | £300 total | £300 | 5% | Insulation, polarity, earth loop tests |

| CERTIFICATION & ADMIN | £900 | 14% | |||

| MCS Certification | Registration, certificate | £200 | £200 | 3% | Installation database entry |

| DNO G98 Application | Grid connection approval | £75 | £75 | 1% | Distribution Network Operator fee |

| Building Regulations | Compliance certification | £150 | £150 | 2% | Part P electrical certification |

| Site Survey | Remote + in-person if needed | £300 | £300 | 5% | Structural, electrical assessment |

| Warranty Administration | Registration, documentation | £100 | £100 | 2% | Panel, inverter, installation warranties |

| Consumer Code Membership | RECC/HIES protection | £75 | £75 | 1% | Dispute resolution, deposit protection |

| TOTAL (No VAT) | £6,500 | 100% | |||

| VAT @ 0% | Qualifying residential install | £0 | £0 | 0% | Zero-rated until March 2027 |

| FINAL TOTAL | £6,500 | 100% |

Labour and Installation Service Costs

Professional installation labour accounts for 35-45% of total project costs, encompassing scaffolding hire, electrician time, system commissioning, and project management. Scaffolding hire for typical two-storey properties costs £300-£800 for 2-3 week periods, with prices varying by property height, access complexity, and regional supplier rates. Bungalows or single-storey buildings may eliminate scaffolding requirements, reducing costs by £300-£500, though installers must ensure adequate fall protection and safe working access.

Electrical installation labour including panel mounting, cable installation, inverter connection, consumer unit modifications, and system testing typically costs £1,500-£3,000 depending on installation complexity and regional labour rates. London and Southeast England installations command 15-25% labour premiums compared to Northern England, Wales, and Scotland due to higher living costs and contractor demand. Complex installations requiring consumer unit upgrades (£300-£800), electrical circuit additions, or extensive cable runs between roof and inverter locations increase labour costs proportionally.

MCS certification administration, DNO application processing, and project coordination contribute £200-£400 to installation costs, covering installer administrative overhead and certification body fees. Reputable installers include these costs in quoted prices rather than adding separate line items, though homeowners should verify quotation breakdowns confirming certification and approval inclusions. Warranties covering installation workmanship typically span 1-5 years, with premium installers offering 10-year labour warranties demonstrating installation quality confidence.

Battery Storage Addition Costs

Battery storage integration adds £4,000-£8,000 to solar installation costs depending on battery capacity and technology type. Popular battery capacities for UK residential installations include 5kWh (£4,000-£5,500), 9.5kWh (£5,500-£7,000), and 13.5kWh (£7,000-£8,500) systems from manufacturers including Tesla Powerwall, GivEnergy, Solax, and Pylontech. Battery costs encompass battery modules, battery management systems, AC or DC coupling equipment, installation labour, and electrical protection devices.

Detailed battery storage costs analysis helps homeowners determine optimal capacity sizing, technology selection, and whether simultaneous or future battery addition offers better value.

Lithium iron phosphate (LiFePO4) batteries dominate 2026 residential installations due to superior safety profiles, longer cycle lives (6,000-10,000 cycles versus 3,000-5,000 for lithium-ion), and stable performance across temperature ranges. Battery warranties typically cover 10-12 years or defined cycle counts, guaranteeing capacity retention (usually 70-80% of original capacity at warranty expiration). Some manufacturers including Tesla and GivEnergy offer extended warranties reaching 15-20 years for premium pricing.

Retrofitting batteries to existing solar installations costs £5,000-£9,000, reflecting higher installation complexity compared to simultaneous solar and battery installation. Retrofit installations require AC coupling (battery connects to AC side of existing inverter) or inverter replacement with hybrid models, with AC coupling adding inverter costs but preserving existing equipment warranties. Homeowners planning future battery addition should specify hybrid inverters during initial installation, adding £200-£500 to upfront inverter costs while simplifying eventual battery integration.

What certifications and approvals do solar installations require?

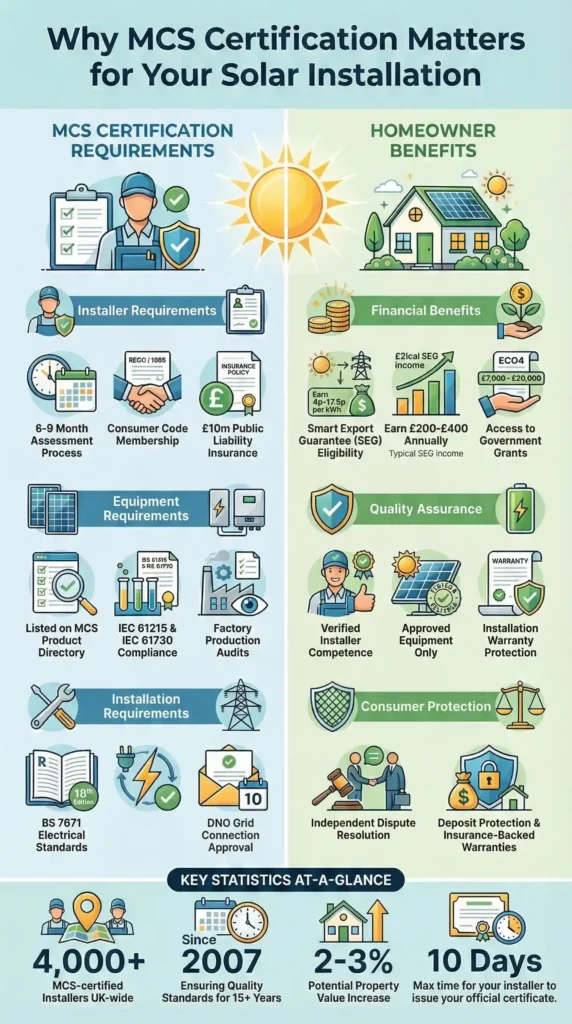

UK solar panel installations require MCS (Microgeneration Certification Scheme) or Flexi-Orb certification for Smart Export Guarantee eligibility, Building Regulations compliance certification, and DNO grid connection approval for systems exceeding 3.68kWp capacity. MCS certification verifies installers meet quality standards, use approved equipment, and follow installation protocols ensuring system safety and performance. Only MCS or Flexi-Orb certified installations qualify for Smart Export Guarantee tariffs paying 4p-17.5p per kWh for grid-exported electricity in 2026, making certification financially essential for most homeowners.

MCS certification proves essential for accessing Smart Export Guarantee payments, but also enables participation in solar panel grants including ECO4 schemes for eligible low-income households. These grants can cover £7,000-£20,000 of installation costs for qualifying properties, making solar accessible to homeowners who might otherwise struggle with upfront investment. Homeowners should verify installer MCS certification before signing contracts to preserve funding eligibility.

Understanding available government grants for solar panels helps homeowners maximize financial support and reduce upfront investment barriers, particularly for those facing affordability challenges or living in fuel poverty situations.

MCS Certification Requirements

MCS (Microgeneration Certification Scheme) represents the UK’s primary quality assurance framework for small-scale renewable energy installations, established in 2007 and government-recognised since inception. MCS certification covers installers, products, and completed installations, with installers demonstrating technical competence, consumer protection commitments, and quality management systems before receiving accreditation. Installer certification requires 6-9 month assessment processes including office-based audits examining business systems and site-based installation assessments verifying practical competence.

MCS-certified installers must employ Nominated Technical Persons (NTPs) qualified in relevant technologies, maintain public liability insurance (minimum £10 million coverage), join approved consumer codes (Renewable Energy Consumer Code or Home Insulation & Energy Systems Quality Assured Contractors Scheme), and undergo regular surveillance audits maintaining certification validity. Consumer code membership provides homeowners with independent dispute resolution mechanisms, deposit protection schemes, and installation warranty insurance if installers cease trading.

Equipment used in MCS-certified installations must appear on the MCS Product Directory, confirming compliance with MCS 005 (Solar PV Standard) and MCS 010 (Product Quality Requirements) through independent third-party testing. Panel manufacturers submit products for testing to standards including IEC 61215 (crystalline silicon terrestrial photovoltaic modules), IEC 61730 (photovoltaic module safety qualification), and additional MCS-specific requirements. Products maintain certification through ongoing surveillance testing and factory production control audits verifying consistent manufacturing quality.

Completed installations receive MCS certificates within 10 working days of commissioning and final payment, listing system specifications including panel quantities and models, inverter details, total installed capacity, estimated annual generation, and installer information. Certificates contain unique reference numbers enabling Smart Export Guarantee provider verification and warranty claim validation. MCS maintains the Installation Database recording every certified installation since 2010, providing government statistical data and homeowner certificate retrieval services.

| Feature / Requirement | MCS-Certified Installation | Non-Certified Installation |

|---|---|---|

| FINANCIAL BENEFITS | ||

| Smart Export Guarantee Eligibility | YES - All suppliers accept | NO - Ineligible for SEG payments |

| Typical Annual Export Income (4kWp) | £200-£400 per year | £0 (cannot claim payments) |

| 25-Year Export Income | £5,000-£10,000 cumulative | £0 |

| ECO4 Grant Eligibility | YES - If homeowner qualifies | NO - Certification required |

| Potential ECO4 Grant Value | £7,000-£20,000 | £0 |

| Property Value Impact | +2-3% (verified installations) | Minimal or negative (unverified) |

| QUALITY ASSURANCE | ||

| Installer Technical Competence | Verified through assessments | Unverified, variable quality |

| Equipment Quality Standards | MCS Product Directory only | Any equipment, quality unverified |

| Installation Standards | BS 7671 18th Edition mandatory | No mandatory standards |

| Building Regulations Compliance | Certified, documented | Self-certified or uncertified |

| Installation Warranty | 1-10 years backed by insurance | Variable, often uninsured |

| CONSUMER PROTECTION | ||

| Consumer Code Membership | RECC or HIES mandatory | No protection |

| Deposit Protection | YES - Up to £5,000 | NO |

| Independent Dispute Resolution | YES - Free service | NO - Legal action only |

| Trading Standards Approval | YES - Verified | NO |

| Insurance-Backed Warranty | YES - If installer ceases trading | NO |

| TECHNICAL & SAFETY | ||

| DNO Grid Connection Approval | Required, documented | May be bypassed illegally |

| Electrical Safety Testing | Comprehensive, certificated | Variable or none |

| Fire Safety Compliance | Verified to standards | Unverified |

| Equipment Warranties | Valid, registered | May be voided by improper installation |

| System Performance Guarantee | Documented, enforceable | Unverifiable claims |

| DOCUMENTATION | ||

| MCS Certificate | Issued within 10 working days | Not available |

| Building Regulations Certificate | Provided | May be absent |

| System Design Specification | Detailed, performance-estimated | Often minimal |

| Equipment Datasheets | Complete set provided | Variable |

| Installation Database Record | YES - National database | NO |

| LONG-TERM IMPLICATIONS | ||

| Property Sale Complications | None - verified installation | Buyer surveys flag concerns |

| Insurance Claims | Fully supported | May be rejected |

| Warranty Claims | Straightforward process | Complicated or impossible |

| System Modifications | Easy to verify compliance | Unknown compliance status |

| Mortgage Applications | No issues | May affect lending decisions |

Flexi-Orb Alternative Certification

Flexi-Orb emerged in 2024 as an alternative certification scheme recognised alongside MCS for Smart Export Guarantee qualification, offering similar quality assurance with potentially streamlined processes. Energy suppliers including Octopus Energy recognise both MCS and Flexi-Orb certificates for export tariff applications, providing homeowners with certification choice. Flexi-Orb certified installers follow comparable quality standards, use approved products, and issue certificates enabling export payment claims.

Flexi-Orb aims to increase installer competition and reduce certification bottlenecks sometimes affecting MCS application processing. Homeowners should verify chosen installers hold valid certification (MCS or Flexi-Orb) before contracting, checking certification status through official directories rather than relying solely on installer claims. Both schemes require installer adherence to consumer protection codes, proper installation standards, and equipment quality verification.

Building Regulations Compliance

Solar panel installations must comply with Building Regulations Part P (Electrical Safety) governing electrical installation safety, requiring competent person scheme membership or Building Control notification. MCS-certified installers typically belong to competent person schemes including NAPIT, NICEIC, or Stroma enabling self-certification of Building Regulations compliance. Installers issue Building Regulations compliance certificates confirming installations meet electrical safety requirements, structural adequacy standards, and fire safety provisions.

Non-certified installers must notify local authority Building Control before commencing work, paying notification fees (£100-£300) and potentially requiring inspection visits verifying compliance. Building Control approval typically extends project timelines by 2-4 weeks and adds administrative costs without providing MCS certification benefits. Homeowners should strongly prefer MCS-certified installers combining Building Regulations compliance, export tariff eligibility, and consumer protection within single certification framework.

Planning permission requirements vary based on property type and location, with most domestic installations qualifying as permitted development requiring no formal applications. Listed buildings, conservation areas, World Heritage Sites, and properties with article 4 directions restricting permitted development require planning permission from local authorities before installation proceeds. Ground-mounted systems exceeding size thresholds (9m² area, 4m height, 3m width/depth) require planning permission regardless of property designation.

What happens after solar panel installation is complete?

Post-installation tasks include system commissioning and testing, MCS certificate receipt, export MPAN allocation from DNOs, Smart Export Guarantee tariff registration, and ongoing system monitoring and maintenance. Homeowners receive handover documentation including MCS certificates, equipment warranties (panels 25-40 years, inverters 5-15 years, installation workmanship 1-10 years), user manuals, system design specifications, and Building Regulations compliance certificates. Proper system monitoring identifies performance issues early, maximising generation and enabling prompt warranty claims if equipment faults develop.

System Commissioning and Handover

Commissioning involves comprehensive testing verifying system operates safely, efficiently, and according to design specifications. Installers conduct electrical tests including insulation resistance measurements (minimum 1 megohm between live conductors and earth), polarity verification ensuring correct wiring, earth loop impedance testing confirming effective earth connections, and RCD (Residual Current Device) operation testing. Solar-specific tests include open circuit voltage measurements, maximum power point tracking verification, and AC output quality assessment ensuring grid synchronisation and harmless export.

Inverter commissioning includes WiFi configuration enabling remote monitoring, charge/discharge parameter programming for battery systems, grid protection settings verification, and firmware updates installing latest software versions. Installers demonstrate monitoring applications showing real-time generation, consumption, export quantities, battery state of charge, and historical performance data. Homeowners receive login credentials for web portals and smartphone applications enabling ongoing system oversight.

Handover sessions educate homeowners on system operation, emergency shutdown procedures (using AC and DC isolator switches), basic troubleshooting, and maintenance requirements. Installers explain monitoring metrics distinguishing normal operation from potential faults, warranty claim processes, and installer contact procedures for technical support. Professional installers provide written handover packs containing contact information, emergency procedures, monitoring access details, and maintenance schedules rather than relying on verbal explanations alone.

Smart Export Guarantee Registration

Smart Export Guarantee (SEG) registration enables homeowners to receive payments for surplus electricity exported to the national grid, with tariff rates in 2026 ranging from 4p-17.5p per kWh depending on supplier and tariff type. Fixed-rate tariffs offer consistent payments year-round (typical range 4p-8p per kWh), while variable and smart tariffs adjust payments based on wholesale electricity prices and demand patterns (reaching 17.5p+ per kWh during peak demand periods).

SEG applications require MCS or Flexi-Orb certificates proving certified installation, export MPANs allocated by DNOs identifying export meters, and smart meter installation or provision for export measurement. Most energy suppliers process SEG applications within 2-4 weeks of receiving complete documentation, with payments commencing from application submission dates or installation completion dates depending on supplier policies. Some suppliers including Octopus Energy backdate payments to installation completion once export MPANs confirm, preventing payment gaps during MPAN allocation delays.

Export tariff selection should consider household generation patterns, consumption timing, battery storage availability, and tariff complexity. Fixed-rate tariffs suit simplicity preferences, providing predictable income without requiring load shifting or smart charging behaviour. Smart tariffs including Octopus Flux and Intelligent Octopus Flux reward strategic battery charging from cheap night-rate electricity (7.5p per kWh) and export during peak evening periods (24p+ per kWh), maximising financial returns for households willing to actively manage systems.

Ongoing Monitoring and Maintenance

Solar panel systems require minimal maintenance but benefit from regular monitoring identifying performance degradation or equipment faults. Monitoring systems track daily, monthly, and annual generation comparing actual output against predicted performance accounting for weather variations. Significant deviation from predictions (typically more than 10-15% below expectations during comparable weather periods) suggests potential issues requiring investigation including panel soiling, shading changes, inverter faults, or cable damage.

Annual visual inspections check for physical damage including cracked panels, loose mounting hardware, cable degradation, or wildlife interference. Birds nesting under panels create fire hazards through accumulated debris and potential cable damage, with bird-proofing mesh (£200-£600 installed) preventing nesting without affecting generation. Panel cleaning frequency depends on location pollution levels and rainfall adequacy, with most UK installations self-cleaning through rainfall. Dry areas, locations near industrial facilities, or agricultural areas benefit from professional cleaning every 1-2 years (£100-£300 per cleaning) improving generation by 2-8%.

Inverter operation monitoring identifies faults requiring manufacturer warranty claims or replacements. String inverters typically last 10-15 years before replacement necessitates, costing £800-£2,400 installed depending on capacity. Microinverters carry 20-25 year warranties, providing longer service lives but requiring scaffold access for individual unit replacements costing £200-£400 per failed unit including labour.

Battery systems require monitoring of cycle counts, capacity fade, and temperature management. Most modern batteries include battery management systems preventing damaging operating conditions, but homeowners should verify batteries remain within manufacturer-specified temperature ranges (typically 5-35°C) and ventilation remains adequate. Battery replacement occurs after 8-15 years depending on usage patterns and technology type, with costs ranging £3,500-£7,000 for direct replacements or lower if battery prices continue declining.

What are common solar panel installation challenges and solutions?

Common installation challenges include roof suitability issues (structural limitations, incompatible roof materials, excessive shading), electrical infrastructure constraints (undersized consumer units, inadequate circuit capacity), planning permission complexities in protected areas, and DNO connection restrictions in high-solar-penetration regions. Experienced MCS-certified installers assess these challenges during surveys, proposing solutions including structural reinforcements, electrical upgrades, alternative mounting solutions, or system design modifications addressing limitations while maintaining cost-effectiveness.

Roof Condition and Structural Challenges

Older roofs approaching renovation requirements may justify delaying solar installation until roof replacement completes, avoiding expensive panel removal and reinstallation costs (£50-£100 per panel plus scaffolding and labour). Roofs showing significant deterioration including missing tiles, damaged flashing, or compromised weatherproofing require repairs before solar installation proceeds, with repair costs ranging £500-£3,000 depending on extent and accessibility. Some homeowners strategically combine roof renovation with solar installation, achieving combined cost savings on scaffolding and project management.

Asbestos roof coverings prevent standard installation approaches due to health hazards and regulatory restrictions on asbestos disturbance. Specialist asbestos removal costs £1,500-£5,000+ depending on roof size and removal complexity, though some installation companies offer non-penetrative mounting systems sitting on asbestos roofs without drilling or disturbing materials. Alternative solutions include ground-mounted systems (if land available) or flat roof installations on garage or extension roofs avoiding asbestos-covered main buildings.

Load-bearing capacity concerns affect some older properties, buildings with compromised structures, or flat roofs with limited load ratings. Structural engineers (£300-£800 per survey) assess load capacities and specify reinforcement requirements if necessary. Reinforcement costs vary from £500 for simple timber strengthening to £3,000+ for major structural modifications. Lightweight thin-film panels reduce system weights but sacrifice efficiency, requiring larger roof areas for equivalent capacity and offering only 12-15% efficiency versus 20-23% for crystalline panels.

Shading and Panel Layout Optimization

Shading significantly impacts solar generation, with even partial shading across small panel portions reducing entire string output in systems using string inverters without optimisation. Microinverters or DC power optimisers prevent shading on individual panels from affecting others, maintaining overall system performance despite sub-optimal conditions. Microinverter systems add £100-£200 per panel premium but justify costs through improved generation in partially shaded installations, recovering additional costs through increased electricity generation over system lifespans.

Strategic panel placement avoiding shaded areas, using multiple roof planes, or accepting smaller system capacities optimises generation within shading constraints. Solar design software including PVsyst, HelioScope, and proprietary installer tools models shading impacts throughout years, quantifying generation differences between layout options. Homeowners should request shading analysis reports comparing design alternatives, enabling informed decisions balancing system size, generation projections, and costs.

Tree removal or significant trimming may improve shading conditions but requires balancing tree preservation values, costs (£500-£2,000 per tree), and potential neighbour relations impacts. Trees protected by Tree Preservation Orders or located in conservation areas require local authority permission before removal or major pruning. Some homeowners accept reduced generation from shaded panels rather than removing established trees providing privacy, aesthetics, or wildlife habitats.

Planning Permission and Conservation Area Restrictions

Listed buildings require planning permission and listed building consent for solar installations, with applications evaluated against heritage impact considerations. Some conservation officers approve installations on rear roof planes invisible from streets while refusing front-facing arrays affecting building character. Planning applications cost £206-£462 depending on application type and local authority, with processing typically requiring 8-12 weeks. Some applications receive approval with conditions specifying panel placement, frame colours matching roof materials, or requirements for removal if buildings change use.

Conservation area restrictions vary by local authority interpretation, with some permitting solar arrays under permitted development rights while others require planning permission for any external alterations affecting building appearance. Homeowners should consult local planning departments before contracting installers, confirming requirements and approval likelihood. Ground-mounted systems in garden areas often face fewer heritage concerns than roof-mounted arrays, providing alternative options if roof installations receive planning refusals.

Article 4 directions remove specific permitted development rights in designated areas, requiring planning permission for alterations normally exempt. Properties affected by Article 4 directions should verify requirements with local planning departments, though many Article 4 directions target extensions and outbuildings rather than solar panels. Planning permission refusals may be appealed, though appeals add 3-6 months to project timelines and incur additional costs (£200-£500 for written representations, £2,000-£10,000 for hearing or inquiry appeals using planning consultants).

Frequently Asked Questions About Solar Panel Installation

How long does solar panel installation take from start to finish?

Complete solar panel installation projects span 4-8 weeks from initial survey through final commissioning in 2026, with physical installation occurring over 1-3 days. Pre-installation stages including property assessment, system design, DNO approval, and equipment procurement account for 3-7 weeks, while post-installation MCS certification and export MPAN allocation require additional 2-4 weeks before SEG payments commence. System complexity, DNO processing times, and planning permission requirements (if applicable) affect overall timelines, with straightforward installations on simple roofs completing faster than complex multi-plane arrays requiring structural modifications.

Do I need planning permission for solar panel installation in the UK?

Most UK domestic solar installations qualify as permitted development requiring no planning permission, provided installations meet specific criteria including maximum 200mm protrusion beyond roof plane, panels do not extend beyond roof edges, and installations on properties within conservation areas maintain street-view invisibility. Listed buildings, properties in conservation areas with visible installations, World Heritage Sites, and locations with article 4 directions require planning permission regardless of installation size. Ground-mounted systems exceeding 9m² area, 4m height, or positioned within 5m of boundaries require planning permission. Flat roof installations permitted since December 2023 must not exceed 1m height above roof surface.

Can solar panels be installed on any roof type in the UK?

Solar panels install on most UK roof types including pitched roofs (tiles, slate, metal), flat roofs (felt, rubber, GRP), and some specialist coverings, though installation methods vary by material. Slate roofs require careful handling due to brittleness, sometimes necessitating tile replacement or custom brackets. Flat roofs use ballasted or fixed mounting systems depending on load capacity and waterproofing accessibility. Thatched roofs generally cannot support solar panels due to fire risks and structural limitations, with ground-mounted systems providing alternatives. Asbestos roofs require specialist handling or non-penetrative mounting avoiding material disturbance. Roof condition, structural capacity, and orientation suitability determine installation feasibility more than roof material type.

What happens if I need a new roof after solar panels are installed?

Solar panel removal and reinstallation during roof replacement costs £50-£100 per panel plus scaffolding (£300-£800) and labour reconnection costs, totaling £1,500-£3,000 for typical residential systems. Homeowners should assess roof condition before solar installation, potentially combining roof renewal with panel installation to avoid future removal costs. Panel warranties typically remain valid through proper removal and reinstallation by qualified installers, though homeowners should verify warranty terms covering removal scenarios. Some installers offer discounted reinstallation rates for customers whose original installations they completed, recognising system familiarity advantages.

How much does solar panel installation cost in 2026?

Solar panel installation costs range from £5,000-£12,000 for complete residential systems in 2026, with typical 4kWp installations averaging £5,500-£7,000 including all equipment, labour, scaffolding, and certification. System costs vary by capacity (3kWp-10kWp residential range), equipment quality (mainstream £150-£250 per panel versus premium £300-£450 per panel), and optional battery storage (adding £4,000-£8,000). VAT zero-rating saves 20% on qualifying residential installations until March 2027. Complex installations requiring electrical upgrades, difficult roof access, or consumer unit replacements increase costs by £500-£2,000. Regional variations affect labour rates, with London and Southeast commanding 15-25% premiums over Northern England, Wales, and Scotland.

Do solar panels require maintenance after installation?

Solar panels require minimal maintenance beyond periodic cleaning (every 1-2 years in dry or polluted areas) and annual visual inspections checking physical damage, mounting security, and cable condition. Most UK installations self-clean through rainfall, though manual cleaning improves generation by 2-8% in soiled panels. Professional cleaning costs £100-£300 per service. Monitoring systems should be checked monthly verifying expected generation, with significant deviations (more than 10-15% below predictions) suggesting investigation requirements. Inverters typically require replacement after 10-15 years (£800-£2,400), while panels maintain 80-90% output for 25-30 years with minimal intervention. Battery systems last 8-15 years before capacity degradation necessitates replacement (£3,500-£7,000).

Can I install solar panels myself without hiring a professional?

DIY solar panel installation is technically legal but strongly inadvisable due to electrical safety risks, warranty invalidation concerns, and Smart Export Guarantee ineligibility without MCS or Flexi-Orb certification. Only certified installer installations qualify for SEG payments ranging 4p-17.5p per kWh, with typical 4kWp systems exporting £200-£400 worth of electricity annually. Professional installations carry public liability insurance covering damage or accidents, provide equipment and workmanship warranties, and ensure Building Regulations compliance. Homeowners with electrical qualifications may perform some work under Building Control notification, though SEG eligibility still requires MCS involvement. Off-grid installations for sheds, caravans, or boats suit competent DIY work where certification proves unnecessary.

What warranties come with professional solar panel installations?

Professional MCS-certified installations include panel product warranties (25-40 years depending on manufacturer), panel performance warranties (guaranteeing 80-92% output retention after 25 years), inverter warranties (5-15 years for string inverters, 20-25 years for microinverters), battery warranties (10-15 years or defined cycle counts), and installation workmanship warranties (1-10 years depending on installer). Premium manufacturers including SunPower offer 40-year comprehensive warranties, while mainstream brands provide 25-30 year panel warranties with 5-12 year inverter coverage. Installation warranties should cover labour, materials, and weatherproofing, with insurance-backed guarantees protecting homeowners if installers cease trading. Warranty registration typically requires MCS certificate details and proof of purchase within 90 days of installation.

How do I choose a reliable solar panel installer?

Reliable solar panel installer selection requires verification of MCS or Flexi-Orb certification status through official directories, consumer code membership (RECC or HIES), customer review examination (Trustpilot, Checkatrade, Which? Trusted Traders), and quotation comparison from minimum three certified installers. Installers should provide detailed quotations specifying equipment brands and models, warranty terms, installation inclusions, and realistic generation estimates based on property location and orientation. Red flags include pressure selling tactics, requests for full payment before installation completion, unrealistic payback claims, or reluctance providing references. Established installers operating 5+ years demonstrate business stability, while newer companies may offer competitive pricing but carry higher business failure risks affecting warranty claims.

Top 8 Solar Panel Installers in Dudley

- October 17, 2025

Top 7 Solar Panel Installers in Walsall

- October 22, 2025